In a groundbreaking move, Boston Dynamics is set to introduce its all-electric humanoid robot, Atlas, into a real-world setting for the first time later this year at a Hyundai manufacturing facility. Unlike its predecessor, the hydraulic version that has garnered attention through captivating video demonstrations since 2013, the latest iteration of Atlas represents a significant leap forward in robot design and functionality. Its deployment highlights an important transition in the industrial landscape, as robots shift from being mere showpieces to essential contributors in commercial manufacturing environments.

What makes Atlas noteworthy? Its design aims to surpass human capabilities in strength and reliability, enabling it to perform tasks that are physically demanding or awkward for human workers. Boston Dynamics spokesperson Kerri Neelon assures us that Atlas will excel in handling heavy and cumbersome items, a representation of what seems to be a vision for a collaborative workforce where humans and robots complement each other.

From Concept to Reality

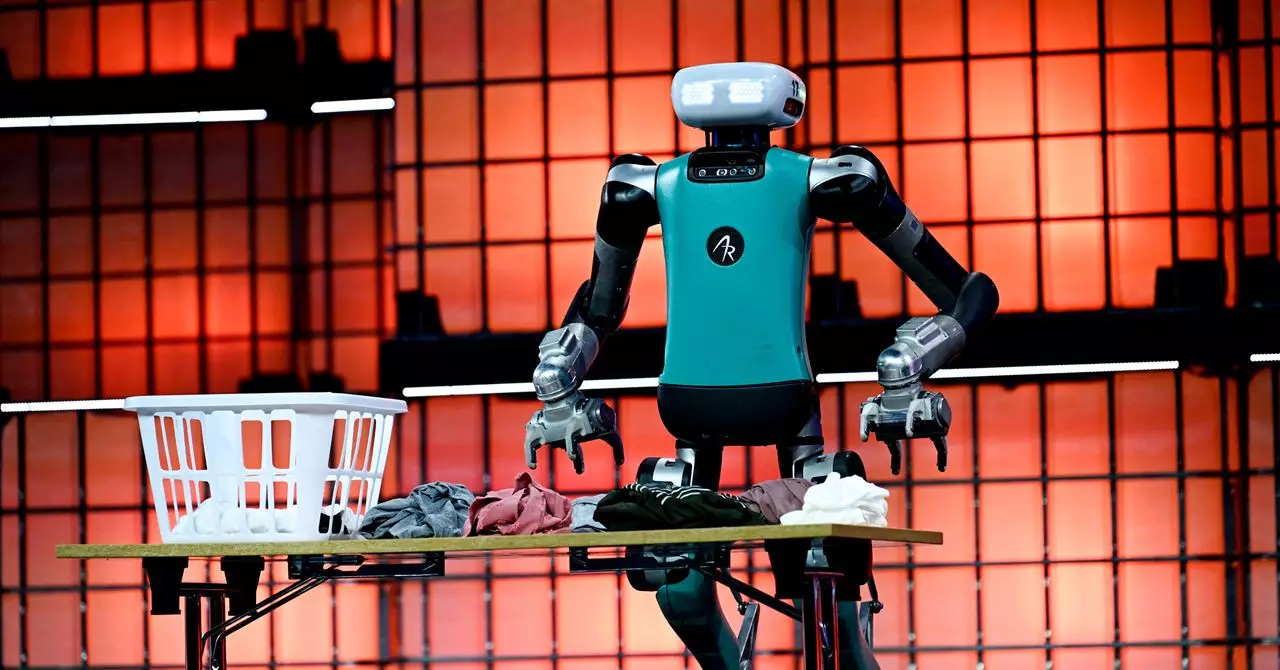

While Boston Dynamics has certainly captured the imagination of the public, Atlas’s upcoming work in the Hyundai factory signifies a bold step into commercial terrain. The apparent duality of human and robot collaboration is bolstered by a trend gaining traction in the industry: multiple humanoid robots are expected to enter the market by 2025. Companies like Agility Robotics and Figure are already testing the waters, with robots like Digit making strides in warehouses, indicating that the age of humanoids operating alongside human counterparts may soon be upon us.

A pivotal report from Goldman Sachs predicts that humanoid robots could create a market worth a staggering $38 billion by 2035. This figure is compelling and serves as a testament to the rapid evolution of robotics, projecting that humanoids will become versatile workers capable of switching between diverse tasks just like their human counterparts. This is a promising shift from the traditional approach of assembly line automation, which has long throttled innovation in manufacturing processes by demanding specialized infrastructure for each task.

Flexibility vs. Precision

Expert Jonathan Hurst, cofounder and chief robot officer at Agility Robotics, emphasizes that while purpose-built automation solutions remain superior for specific tasks, the flexibility offered by humanoid robots can yield greater productivity when tasks do not call for non-stop operations. Essentially, manufacturing environments might soon witness machines that are not only valuable for efficiency but also for their versatility. As factories become safe spaces for automation, Boston Dynamics recognizes the necessity of creating robots, like Atlas, that can navigate the broader human environments.

Neelon points out, “We live in a human-first world, so we should build a robot that reflects that.” This statement captures the ethos behind the design principles of Atlas. As robots begin to transition into human-dominated spaces, their design must reflect our world in both the functionality and appearance to ensure smooth interactions. This endeavor not only demands a leap in technology but also challenges our perceptions of robots as tools versus partners.

Addressing Challenges in the Industry

However, the journey from conception to realization is far from straightforward. For instance, the highly anticipated Tesla Optimus robot has received mixed reactions. Initial demonstrations raised eyebrows, as it became evident that some of the showcased capabilities were reliant on human control, casting doubt on the robot’s potential for independence. Such instances reveal the hurdles humanoid robotics must clear before becoming widely accepted in operational settings.

Despite ambitious claims from Tesla’s Elon Musk regarding mass production, external factors, such as geopolitical challenges affecting supply chains for essential components like rare-earth metals, could stymie rapid development efforts. This indicates a need for resilience and adaptability as the robotics industry grapples with complex global dynamics while innovating at an unprecedented pace.

The fusion of human intelligence and robotic capability is slowly materializing, bringing with it both excitement and scrutiny. The development and implementation of humanoid robots like Atlas represent not just a technological advance, but a cultural shift that forces us to rethink labor, productivity, and the very essence of work in an increasingly automated future. The potential promises to be thrilling, but the path ahead is laden with both opportunity and caution.