The escalating concerns surrounding environmental degradation and sustainability have prompted significant transformations across various industries, particularly in battery technology. With the demand for efficient and eco-friendly energy storage solutions increasing, researchers are faced with the dual challenge of improving battery performance while reducing dependency on harmful materials. A novel study published in the Chemical Engineering Journal critiques traditional lithium batteries, which predominantly rely on fluorinated compounds such as polyvinylidene fluoride (PVDF) and lithium hexafluorophosphate (LiPF6). The implications of these findings lay the groundwork for an environmentally friendly approach to battery design.

Traditional lithium battery systems, while efficient, come with substantial environmental costs. The fluorinated materials commonly employed not only contribute to toxic byproducts—highlighted by the release of hydrogen fluoride (HF)—but also face mounting regulatory scrutiny. The European Union’s recent initiatives to restrict per- and polyfluoroalkyl substances (PFAS) are indicative of a broader movement towards stringent environmental safeguards. PVDF, for instance, is recognized for its stability but poses significant ecological challenges given its non-biodegradable nature and the potential health risks associated with HF emissions.

This scenario necessitates the urgent need for alternative materials that can deliver performance comparable to, or exceeding that of, fluorinated counterparts while adhering to emerging regulatory frameworks.

Researchers from POSTECH in collaboration with Hansol Chemical have risen to meet these challenges by developing a groundbreaking fluorine-free binder and electrolyte system. The newly introduced lithium perchlorate (LiClO4, LC)-based electrolytes, combined with a non-fluorinated aromatic polyamide (APA) binder, offer a sustainable route to battery technology that mitigates the toxic impacts of traditional materials.

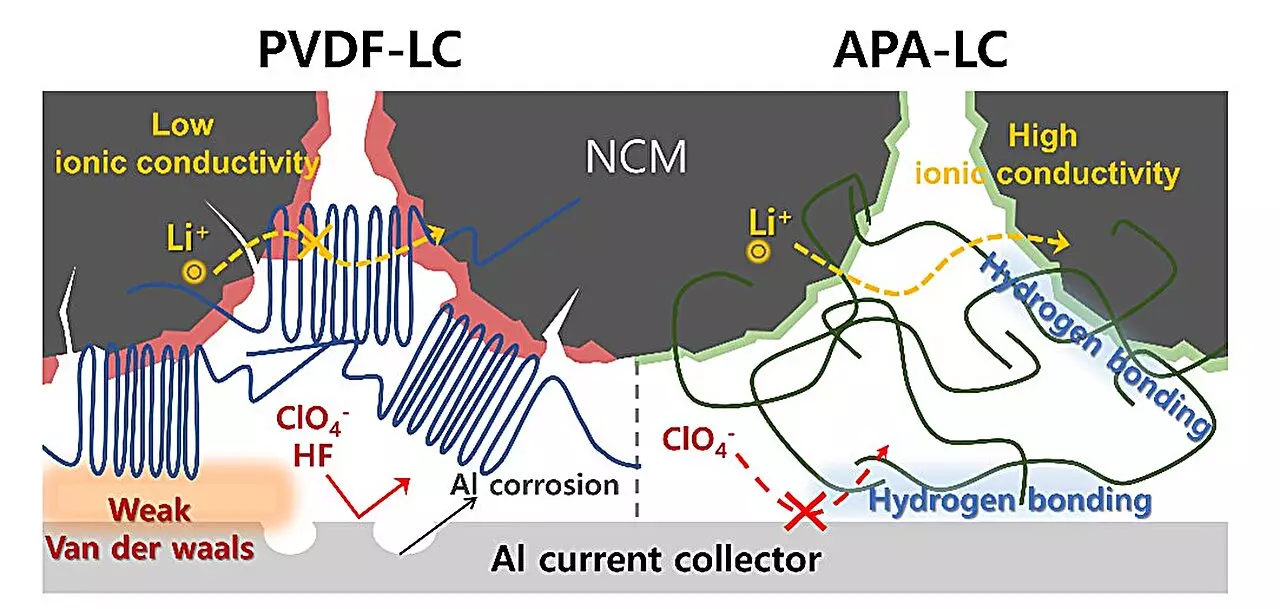

The APA-LC system fundamentally alters the dynamics of ion transfer and bonding within batteries. The innovative APA binder enhances the attachment between the active material within the cathode and its aluminum current collector, which serves to substantially reduce the risks of electrode corrosion within the electrolyte. This vital advancement not only enhances performance but also plays a critical role in extending the lifespan of the battery.

The experimental results speak volumes: the APA-LC system outperformed its fluorinated predecessors, showcasing heightened oxidation stability and a remarkable 20% retained capacity after 200 cycles at a rapid charge/discharge rate of 1C. These findings underline a critical shift in the battery landscape, showcasing that non-fluorinated systems can achieve performance benchmarks that were previously constrained by fluorinated chemistries.

Moreover, the newly developed high-capacity 1.5 Ah pouch cell reinforces the practical applicability of the APA-LC technology. With strong performance during fast-charging trials and excellent discharge capacity, Professor Soojin Park’s assertion that this system could redefine battery industry sustainability is well-founded.

The implications of transitioning to fluoride-free battery technologies are manifold. Not only do they comply with impending environmental regulations, but they simultaneously position companies like Hansol Chemical on a path to secure a significant market share in the burgeoning eco-friendly battery segment. As Managing Director Young-Ho Yoon noted, this strategic focus places the company at the forefront of the secondary battery materials market, projected to reach KRW 1.7 trillion by 2026.

This innovative approach is not just a technical achievement; it represents a paradigm shift in an industry that has long relied on harmful substances. As environmental compliance becomes prioritized, the APA-LC system highlights the potential for manufacturers to align economic viability with ecological responsibility.

The development of a fluorine-free battery system marks a pivotal moment in battery technology, representing a viable pathway towards sustainability and enhanced performance. The collaborative work of POSTECH and Hansol Chemical signifies not just a response to regulatory pressures but a bold step toward redefining industry standards. This innovation serves as a model for future research and development, fostering an energy landscape that prioritizes both high-performance solutions and ecological responsibility. As the world pivots toward greener technologies, such advancements offer hope for a cleaner, more sustainable future.