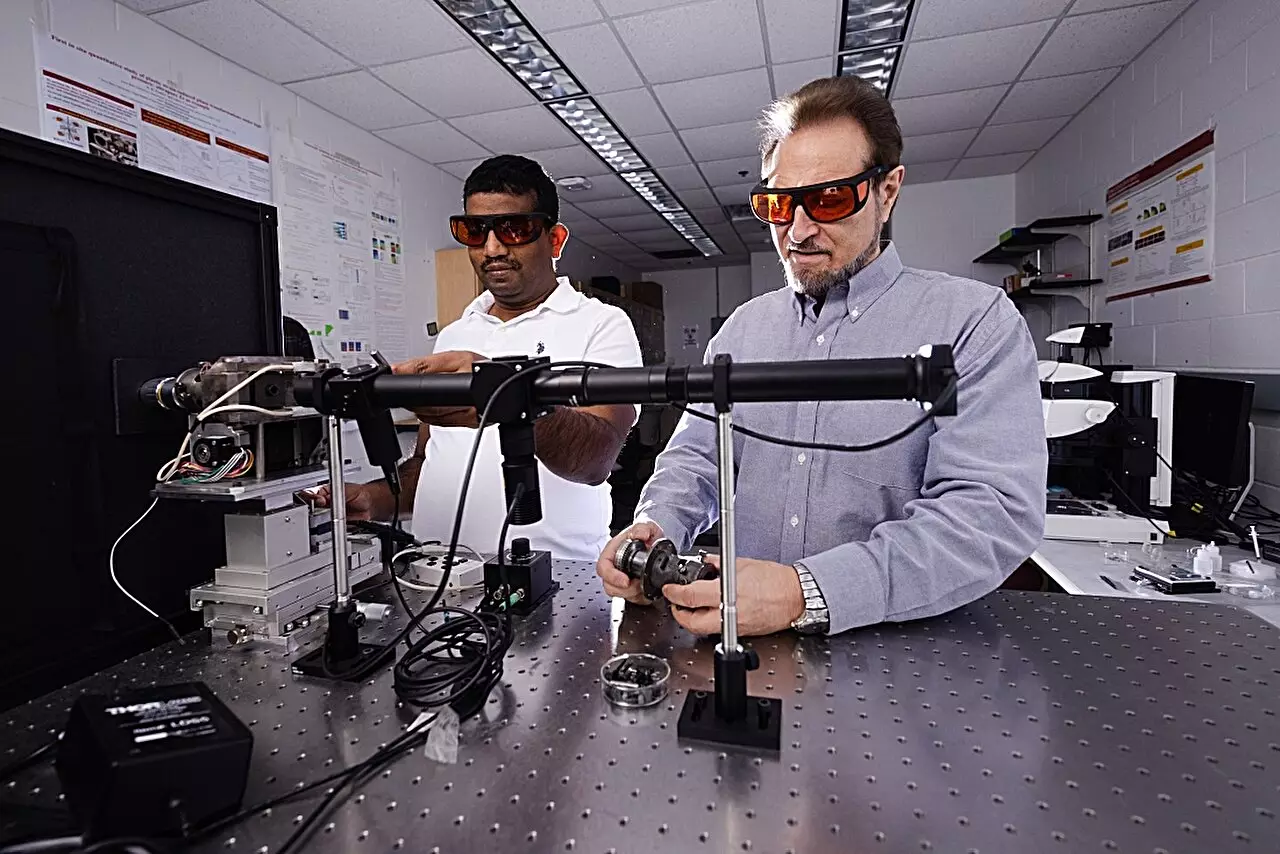

Valery Levitas, a pioneering figure in the field of material science, represents the cutting edge of research at the intersection of various scientific disciplines. When Levitas relocated to the United States in 1999, he brought with him an innovative tool—the rotational diamond anvil cell. This device facilitates the in-situ examination of materials under extreme conditions by applying pressure and shear to samples trapped between two diamonds. Levitas and his team from Iowa State University have refined this technique to explore the transformative behaviors of materials, particularly silicon, under unique mechanical strains, leading to groundbreaking findings that are set to challenge existing paradigms in material science.

Understanding Phase Transformations in Silicon

Silicon, a fundamental component in the electronics industry, is well-studied under high-pressure conditions. However, Levitas and his collaborators have ventured into uncharted territory by investigating how silicon behaves under both pressure and plastic shear deformation. Their research, recently published in *Nature Communications,* reveals that silicon exhibits extraordinary phase transformations when subjected to these specific conditions. Notably, silicon’s Si-I crystal phase can transition to the Si-II phase at significantly lower pressures than previously thought—dropping from 16.2 gigapascals to just 0.3 gigapascals, thanks to the application of plastic deformations.

The implications of these findings extend far beyond theoretical interest; they signal a potential revolution in how materials are engineered for various applications. The ability to manipulate silicon’s properties at such low pressures allows for the creation of novel materials that could redefine electronic components and devices.

The methodology employed by Levitas and his team is as innovative as the findings themselves. They conducted experiments using various particle sizes of silicon, examining three distinct scales: 1 micrometer, 30 nanometers, and 100 nanometers. By utilizing the rotational diamond anvil cell, they were able to induce plastic strains that diverge from typical high-pressure approaches. This departure from tradition enables an exploration of “plastic strain-induced phase transformations,” which had previously been overlooked in research.

Levitas emphasizes that the focus of their experiments is not to merely alter the shape of materials but to transform their microstructures. This shift in microstructure is crucial, as it lays the foundation for phase transformations that can yield dramatically different physical properties. By considering seven phases of silicon, the research demonstrates the complex lattice structures and resultant characteristics that could hold vast potential for practical applications.

The commercial viability of Levitas’s work cannot be overstated. Traditional methods of achieving phase transformations in materials often involve impractical levels of pressure. However, the lessons learned from manipulating silicon at lower pressure points bear significant promise for industrial processes. Industries reliant on high-performance materials could leverage these new findings to enhance the properties of semiconductors and other technologically relevant materials without the burdensome requirements of extremely high-pressure environments.

Levitas’s assertion that such a methodology opens doors to creating nanocomposites with optimal electronic and mechanical properties resonates across various sectors. From electronics to energy storage, the capacity to tailor materials to industry specifications and requirements stands to drive innovation and efficiency.

The groundbreaking research led by Levitas and his collaborators marks a pivotal advancement in material science. By successfully demonstrating the ability to induce significant phase transformations in silicon with low-pressure plastic deformations, they challenge the conventional wisdom that typically guides the field. As material scientists continue to explore the multifaceted interactions of pressure, shear, and microstructure, we stand on the brink of a new era—one in which the manipulation of material properties may become routine, leading to innovations that will shape the future of technology and engineering.

Levitas’s work is a testament to the importance of interdisciplinary approaches in scientific research. By drawing on advanced mechanics, physics, material science, and mathematics, the team not only broadens our understanding of materials but also lays the groundwork for practical applications that can enhance both industry and everyday life. As we delve deeper into this fascinating intersection, the potential for discovery knows no bounds.