The continuous advancement in nuclear fusion technology suggests a promising future for clean energy. Among the key challenges faced by scientists and engineers in this field is the development of advanced shielding alloys that can withstand the extreme conditions of fusion reactors. In recent efforts led by the Oak Ridge National Laboratory (ORNL), researchers have harnessed the power of artificial intelligence (AI) to discover new alloy compositions tailored for enhanced performance in nuclear environments. This marriage of material science and AI not only expedites the traditional trial-and-error methods but also opens new avenues for innovation in energy production.

The findings from ORNL, published in the journal *Scientific Data*, underline a critical leap toward improving the functionality and efficiency of nuclear fusion reactors. The study was initiated under the direction of David Womble, former AI Initiative Director at ORNL, and has continued to gain momentum under the Artificial Intelligence for Scientific Discovery (AISD) program. The crux of the research focuses on creating alloys capable of surviving severe thermal conditions while maintaining structural integrity. With nuclear fusion aiming to replicate the sun’s energized reactions, the materials used must resist intense heat and radiation, a tall order for conventional alloys primarily based on tungsten.

Historically, alloy development has been constrained by the limited scope of traditional materials. Tungsten has served as the backbone of shielding materials; however, its deficiencies in stability at high temperatures have prompted researchers like AI scientist Massimiliano Lupo Pasini to rethink the strategy for creating alternatives. “These alloys are needed to achieve exceptional performance at very high temperatures,” Lupo Pasini emphasizes, shedding light on the urgent need for innovation in this domain.

The challenge of alloy discovery is compounded by the vast number of potential metallic combinations, making the traditional materials research process both time-consuming and unpredictable. By employing AI algorithms, researchers can proactively sift through countless possibilities to identify new candidates quicker and more accurately than conventional approaches allow.

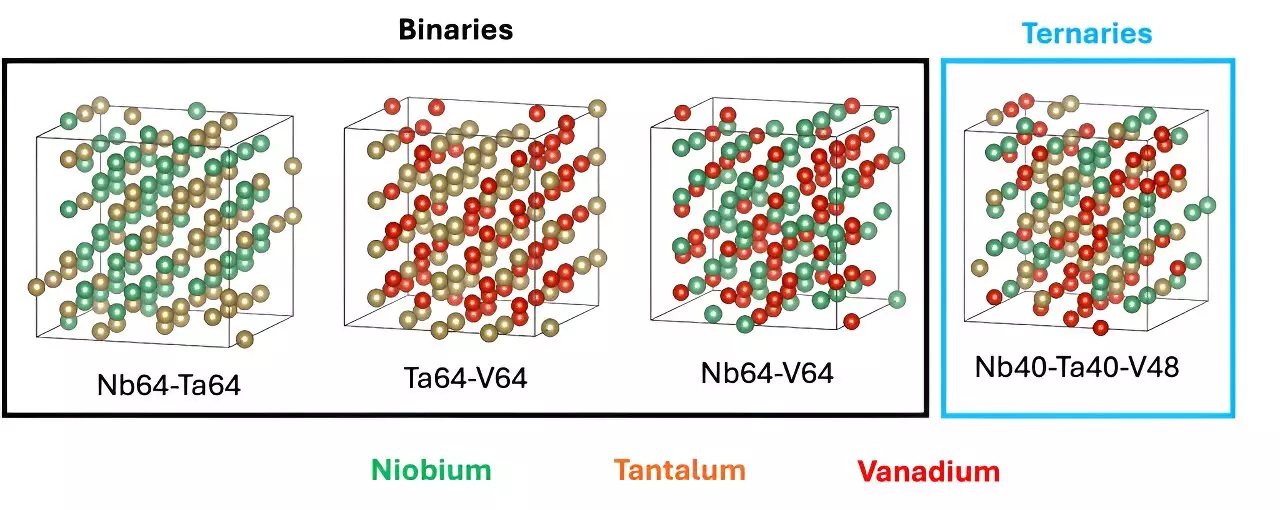

The collaborative efforts of the research team—including scientists from various ORNL divisions—were pivotal in developing an AI framework capable of accurately predicting viable alloy compositions. Their strategy was to construct a robust database that would inform the AI model about potential combinations of different elements. Through the integration of machine learning, the team successfully identified three initial elements worthy of experimental testing. However, the journey does not stop at mere identification.

While the AI-generated database marks a pivotal first step, it represents only one facet of a larger project aimed at developing high entropy alloys. Lupo Pasini noted that optimizing these materials capable of performing under extreme conditions involves the exploration of at least six elemental variables. Thus, real-world testing and refinement are inevitable as researchers strive to actualize these AI recommendations.

Building an AI model that accommodates the wide-ranging backgrounds of various materials is no small feat. The complexity of quantum mechanical simulations further complicates the process of verifying predicted outcomes. The research team faced substantial hurdles in computational demands—the data generation alone required extensive use of advanced supercomputers like Perlmutter at Lawrence Berkeley National Laboratory and Summit at ORNL, consuming over a year of computational effort.

The data captured through these experiences not only serves as the foundation for AI-enhanced alloy discovery but also addresses the limitations posed by traditional computational methods. “This work sets a precedent for future investigations in our field,” said Lupo Pasini.

The next essential phase for researchers involves employing the data generated to optimize the AI model’s capabilities. By fine-tuning the ratios of different elements in the alloy mixtures, scientists aim to accelerate material discovery significantly, streamlining the experimental process inherently filled with trial and error.

Ultimately, the intersection of AI technology and material science is poised to lead to groundbreaking advancements in fusion technology. By refining these alloys, we not only aim to improve the performance of nuclear reactors but also edge closer to a sustainable energy future powered by fusion. The work being carried out by the ORNL team exemplifies the transformative potential that AI holds in material discovery and highlights the urgent need for collaboration between disciplines to tackle the challenges of tomorrow’s energy demands.